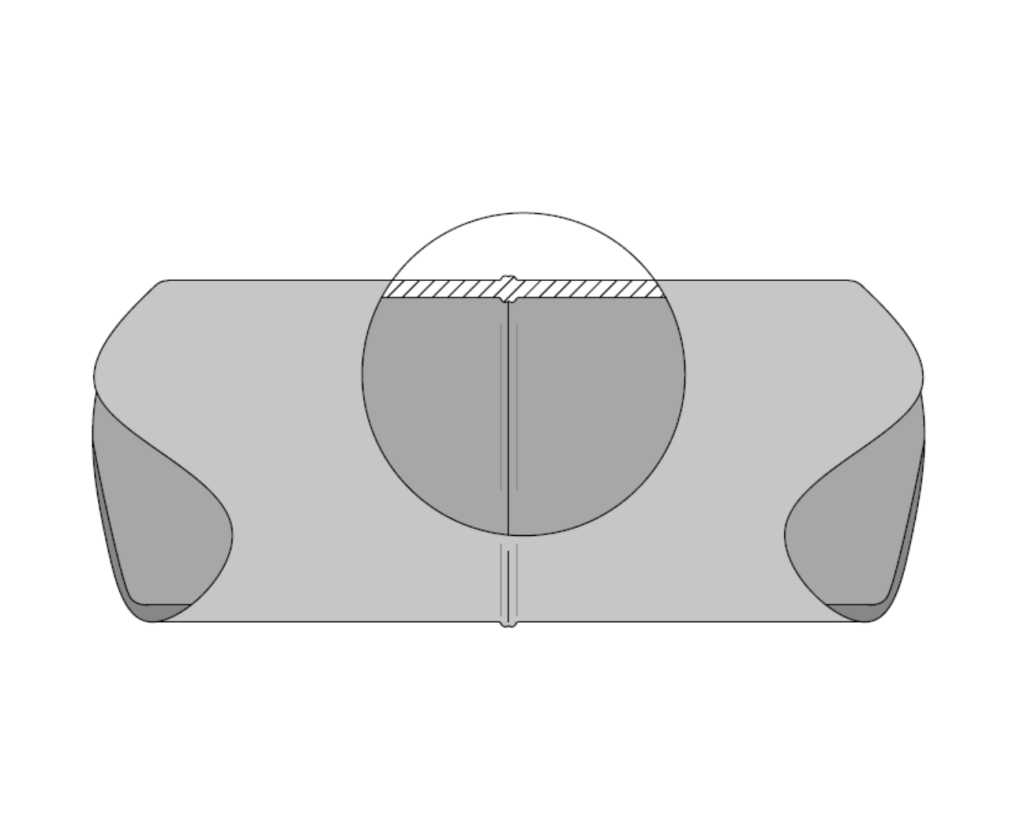

Butt-Fusion Jointing

Butt-fusion jointing is a thermofusion process which involves the simultaneous heating of the ends of two components which are to be joined until a melt state is attained on each contact surface. The two surfaces are then brought together under controlled pressure for a specific cooling time and homogeneous fusion is formed upon cooling. The resultant joint is resistant to end thrust and has comparable performance under pressure to the pipe.

Electro-Fusion Jointing

All electrofusion fittings employ the same basic principle. The socket of the fitting incorporates an electrical heating coil. An electrofusion control unit (ECU) supplies the electrical energy necessary to heat the coil. When the coil is energised the material adjacent to it melts and forms an expanding pool which comes into contact with the surface of the pipe. The continued introduction of heat energy causes the pipe surface to melt and a mixing of pipe melt and fitting melt takes place; this is vital to produce a good weld. Following the termination of the heat cycle, the fitting and pipe are left to cool and the melted material solidifies to form a sound joint.

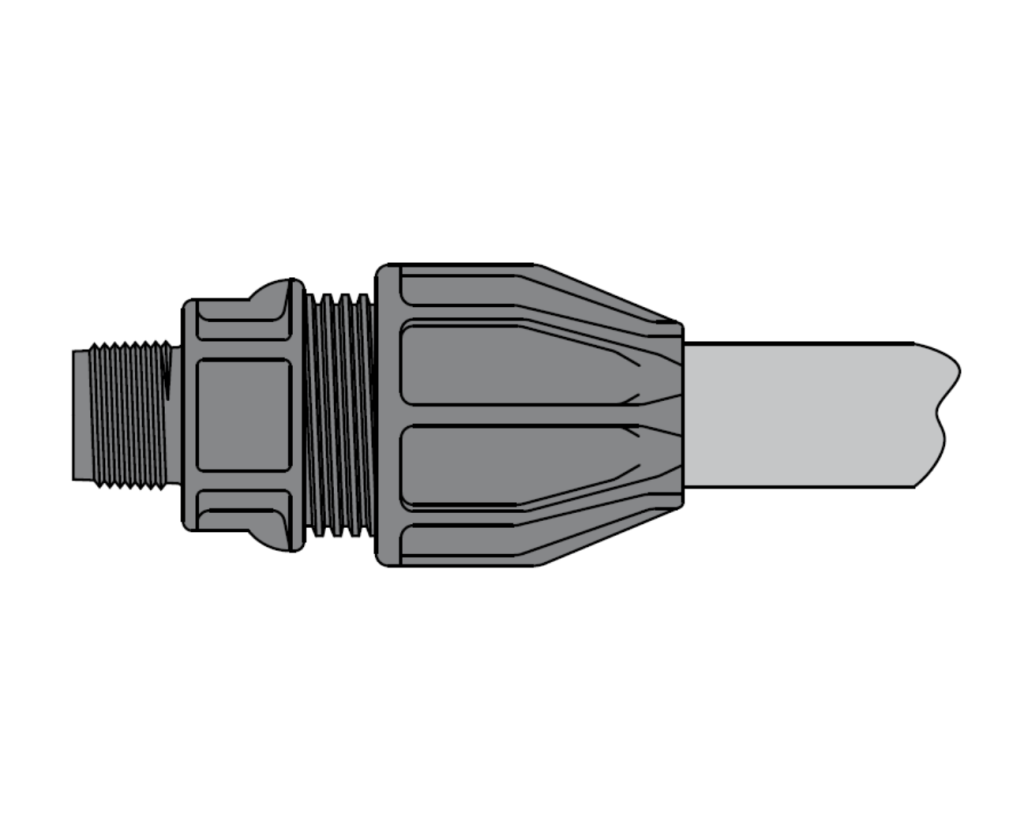

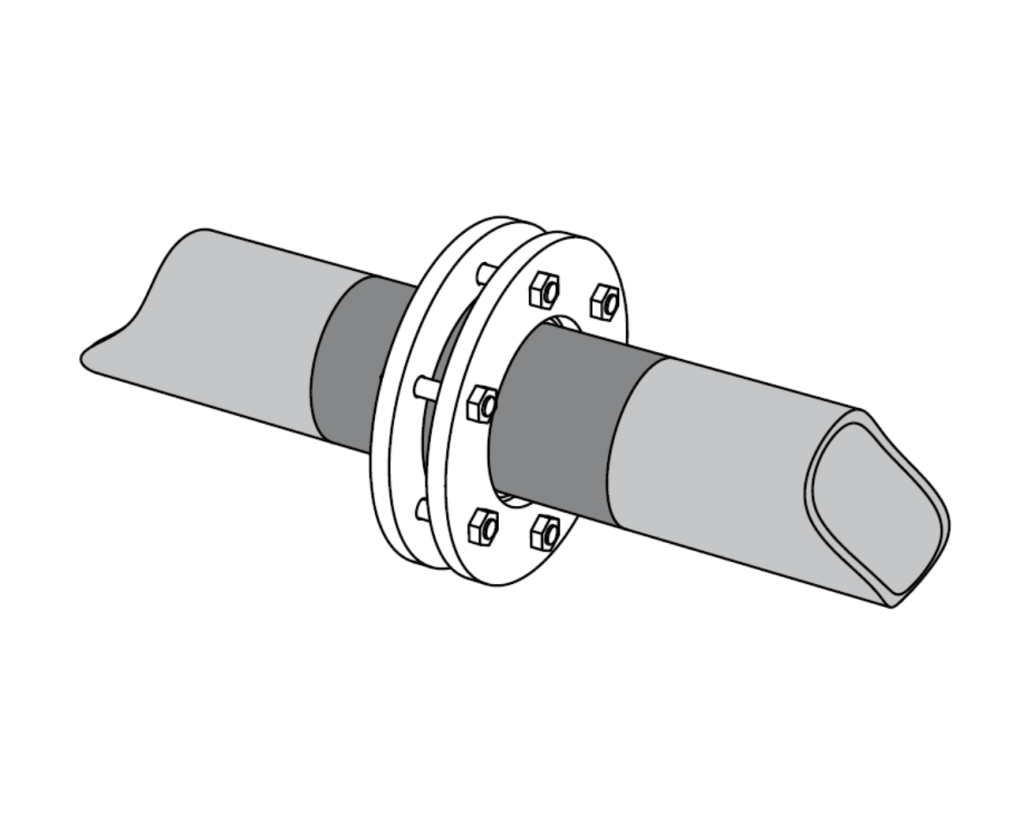

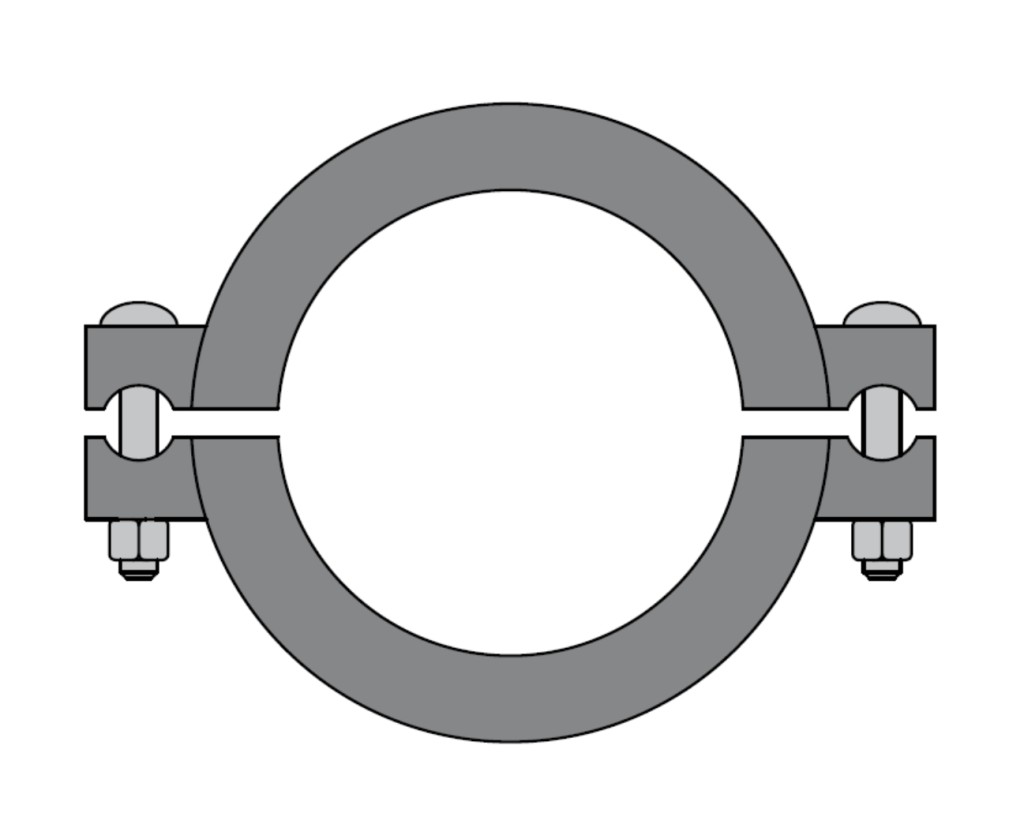

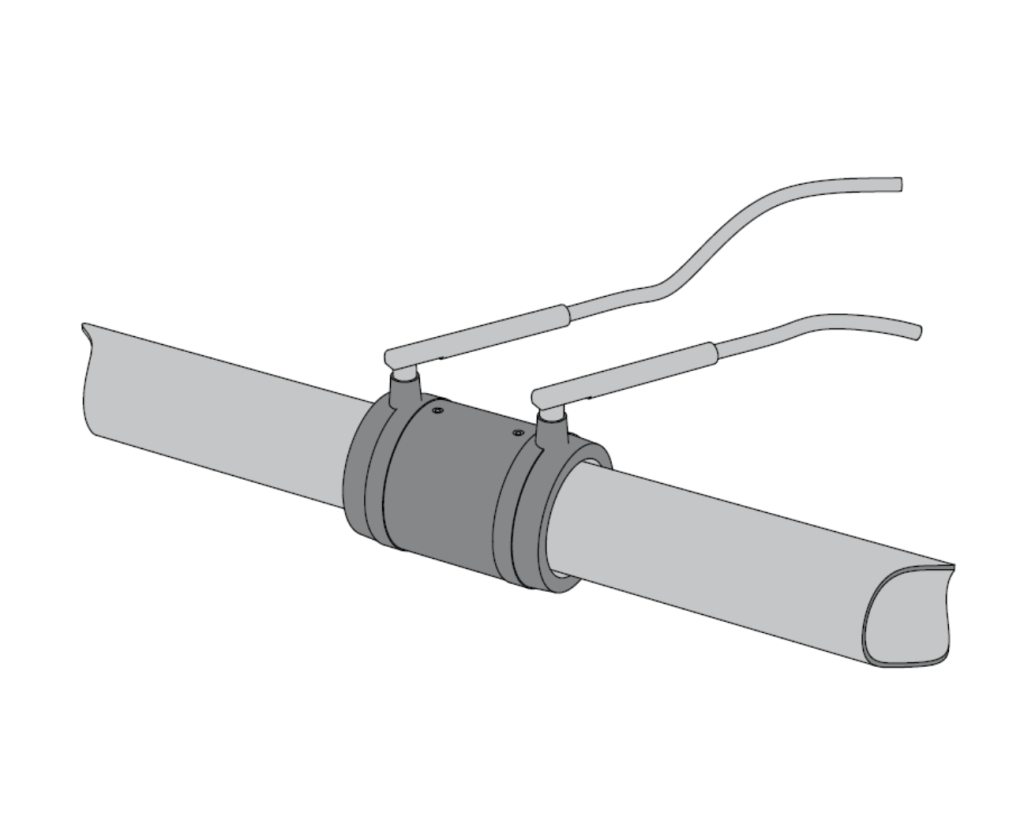

Non-permanent Jointing

Non-permanent jointing involves the use of mechanical fittings to join pipes together. Such fittings include compession fittings, flanging and clamping.