TOP-PIPE HDPE Drainage Systems provide a complete solution for all types of drainage needs, both for above the ground and below the ground applications. The system is manufactured using high density polyethylene, which offers numerous advantages over conventional materials because of its inherent characterics. The toughness and durability of HDPE provides a drainage solution that combines extraordinary chemical resistance with high flexibility and great impact resistance. As such, these characteristics have made HDPE the preferred piping material internationally.

TOP-PIPE HDPE Drainage Systems are manufactured to EN 1519 Standards and are available in diameters from 32mm up to 315mm). To ensure TOP-PIPE maintains the highest quality, our pipes are manufactured using 100% virgin PE100 raw material sourced from the world’s leading plastic suppliers.

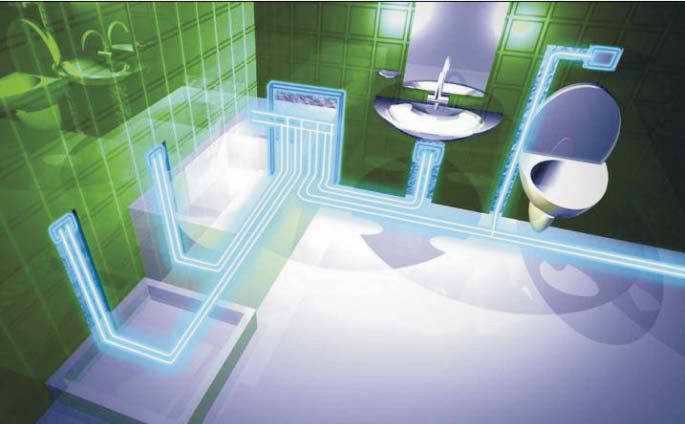

TOP-PIPE HDPE Drainage Systems can be used in a broad range of applications in both the Plumbing and Industrial markets, such as greasy, sanitary and trade waste; laboratory waste; waste network ventilation; and rainwater drainage due to its high resistance to a wide range of chemicals. The systems can operate at both low (as low as -40°C) and high (up to 95°C) temperatures. This makes TOP-PIPE HDPE Drainage Systems the perfect solution for commercial, residential and industrial buildings; hospitals; laboratories; and hotels.